3D-printed aluminum alloy achieves strength milestones for lighter aircraft components.

Printable aluminum alloy sets strength records, may enable lighter aircraft parts | MIT News

Breakthrough in Aluminum Alloys: Printable Metal Technology at MIT

Introduction to Printable Aluminum Alloy

Engineers at MIT have made a significant advancement in materials science by developing a printable aluminum alloy that can endure high temperatures and boasts strength five times greater than conventional aluminum. This innovation harnesses a combination of aluminum and various elements chosen through sophisticated simulations and machine learning, dramatically reducing the number of material combinations that needed examination.

Traditional vs. Innovative Approaches

Traditionally, the creation of new alloys often involves evaluating over a million potential combinations. However, the MIT team employed a machine learning-based method that narrowed this search down to just 40 compositions. This efficient approach led to the identification of a new high-strength, printable aluminum alloy that meets modern engineering demands.

Performance and Potential Applications

After printing and testing the new alloy, the team confirmed that its strength matched that of the strongest aluminum alloys produced via traditional casting methods. The researchers foresee a host of applications for this alloy across various industries, particularly in manufacturing more robust, lightweight, and heat-resistant products. A prime example is the use of this alloy for fan blades in jet engines, which are typically made from heavy titanium or expensive advanced composites.

“If we can substitute a lighter, stronger material, we could achieve significant energy savings in the transportation sector,” explains Mohadeseh Taheri-Mousavi, who spearheaded the project as a postdoctoral researcher at MIT and is now an assistant professor at Carnegie Mellon University.

Diverse Applications and Future Innovations

Due to its unique properties, this new printable aluminum alloy could also find use in advanced vacuum pumps, luxury automobiles, and cooling systems for data centers, further showcasing its versatility. According to John Hart, Professor and head of the Department of Mechanical Engineering at MIT, the capabilities of 3D printing allow for complex geometries, material conservation, and unique designs that this alloy can support.

The Science Behind the Innovation

The inception of this project can be traced back to a 2020 class at MIT, where Taheri-Mousavi learned to utilize computational simulations for alloy design under the guidance of Professor Greg Olson. The class was tasked with creating an aluminum alloy that surpassed existing printable aluminum alloys. Acknowledging that the strength of aluminum largely hinges on its microstructure—the size and density of its precipitates—the class utilized simulations to explore combinations of aluminum with various elements. Despite extensive research, they did not yield the desired strength levels.

This led Taheri-Mousavi to ponder whether machine learning could offer a more effective solution. “At some point, many factors contribute nonlinearly to material properties, and it can be overwhelming,” she states. Thanks to machine learning tools, the team could pinpoint crucial components that affect material properties, leading to a more efficient exploration of design parameters.

Machine Learning and Materials Development

In the latest study, Taheri-Mousavi took the initiative to identify a stronger aluminum alloy recipe using machine learning techniques. This allowed her to efficiently analyze the interconnected properties of various elements to uncover correlations that would yield a superior product.

Using just 40 compositions of aluminum mixed with different elements, the machine-learning method quickly identified an alloy exhibiting a higher volume fraction of small precipitates, resulting in greater strength than previous research had achieved over a million simulations without machine learning.

3D Printing: A Game-Changer for Alloy Creation

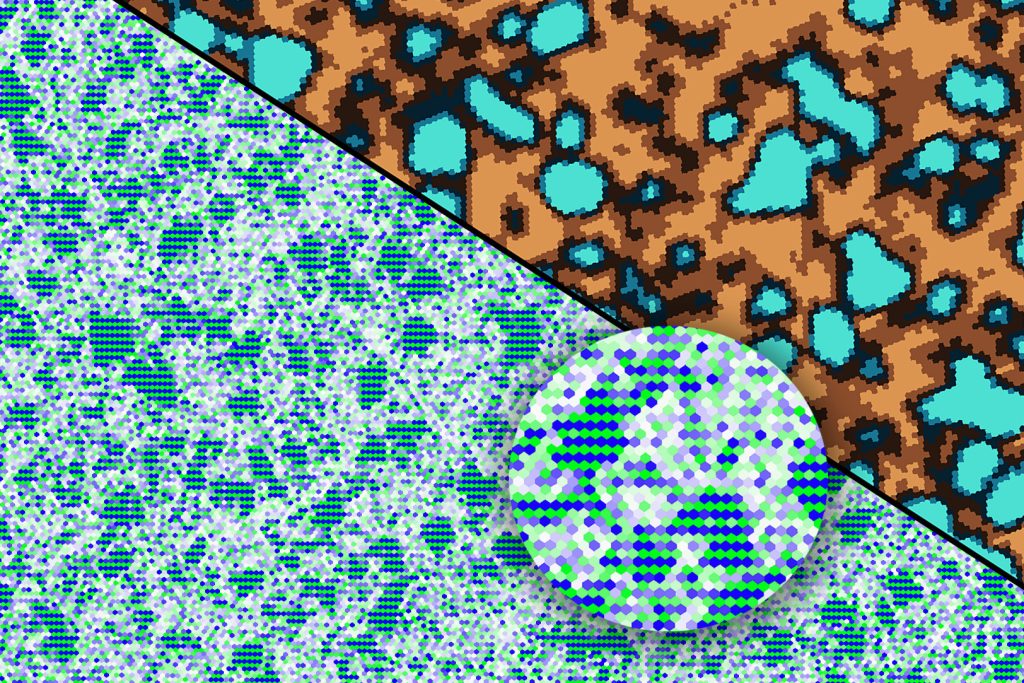

To physically realize this high-strength alloy, the researchers determined that 3D printing would be more effective than traditional casting methods. In casting, molten aluminum is poured into molds and allowed to cool—an extended cooling period can encourage the growth of larger precipitates, which compromises strength.

Additive manufacturing techniques like laser bed powder fusion (LBPF) offer a quicker cooling and hardening process. LBPF involves layering powder in a specific pattern, which is then rapidly melted and solidified using a laser. The team discovered that this rapid cooling enables the formation of small precipitates, thereby preserving the alloy’s heightened strength predicted by their machine learning approach.

John Hart emphasized, “Sometimes, we must think about how a material can be made compatible with 3D printing. This approach opens new avenues due to the fast cooling rates afforded by the process.”

Collaboration and Practical Application

Following the successful formulation of the printable powder based on their newly identified aluminum alloy, the researchers collaborated with team members in Germany to print small samples. Once printed, these samples were analyzed back at MIT to test strength and study microstructures.

The results reaffirmed the predictions generated by their machine learning algorithms: the new alloy was five times stronger than a traditional cast counterpart and 50% stronger than alloys developed using conventional simulations. The microstructure provided evidence of a higher volume of small precipitates and demonstrated stability at temperatures reaching up to 400 degrees Celsius—an impressive feat for an aluminum alloy.

The Road Ahead: Optimizing Aluminum Alloys and More

The research team is now applying similar machine-learning techniques to enhance additional properties of the aluminum alloy, paving the way for future innovations in 3D printing and alloy design.

“Our methodology opens new doors for anyone interested in 3D printed alloy development,” Taheri-Mousavi states. “I envision a future where passengers gazing out of airplane windows might see fan blades made from our advanced aluminum alloys.”

Conclusion

MIT’s advancements in printable aluminum alloys signify not only a major leap in materials science but also offer practical solutions that could revolutionize numerous industries. As the capabilities of machine learning and 3D printing continue to converge, the potential for creating superior materials and products is boundless.

Thanks for reading. Please let us know your thoughts and ideas in the comment section down below.

Source link

#Printable #aluminum #alloy #sets #strength #records #enable #lighter #aircraft #parts #MIT #News