Freeform secures $67M in Series B funding to enhance laser AI manufacturing.

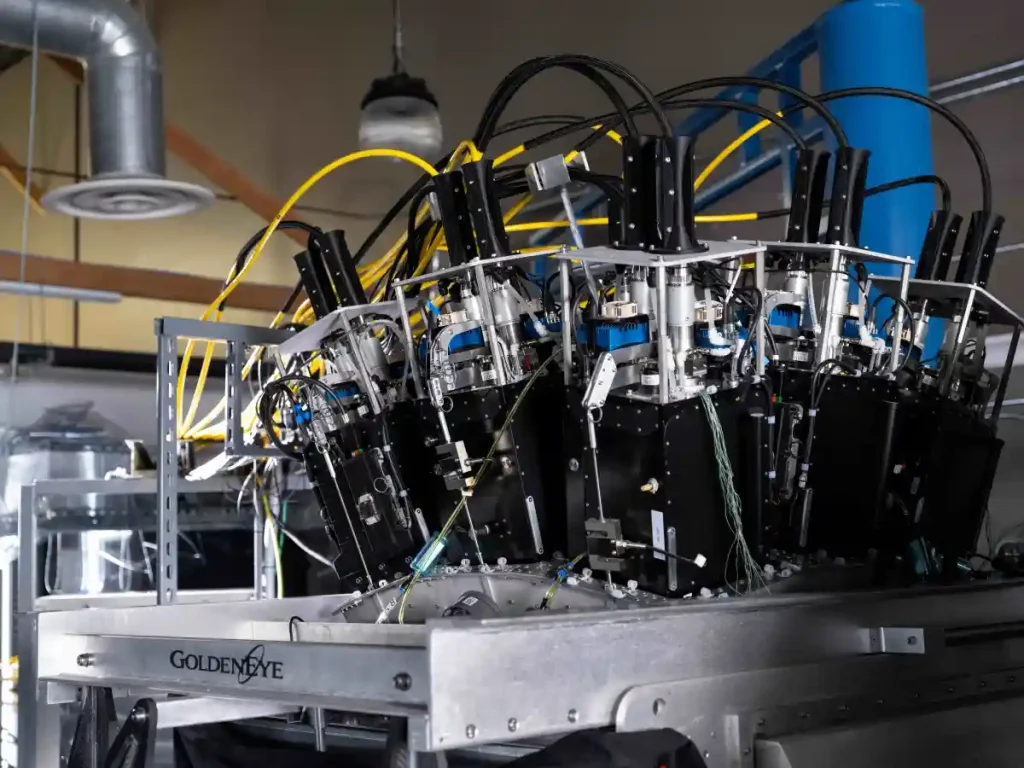

Image Credits:Freeform

Freeform’s $67 Million Funding: Revolutionizing Metal 3D Printing

Tech investors remain persistent in their pursuit of revolutionary manufacturing methods capable of producing physical products as swiftly and efficiently as developing software. Recently, Freeform—a startup focused on innovative metal 3D printing systems—announced it has successfully raised $67 million in Series B funding to expand its manufacturing capabilities.

Overview of Freeform’s Breakthrough Technology

The funding round attracted reputable investors, including Apandion, AE Ventures, Founders Fund, Linse Capital, NVidia’s NVentures, Threshold Ventures, and Two Sigma Ventures. While Freeform chose not to disclose its post-funding valuation, industry data from Pitchbook estimates it to be about $179 million.

The Vision Behind Freeform

Erik Palitsch, CEO and co-founder of Freeform, articulated that this influx of capital will enable the company to enhance its existing GoldenEye printing system. This system currently employs 18 lasers to fuse metal powders into precise components. However, the upcoming version, known as Skyfall, aims to significantly upgrade production capabilities by utilizing hundreds of lasers for the mass production of thousands of kilograms of metal parts each day.

Palitsch and co-founder/president Thomas Ronacher initiated this endeavor in 2018. Their backgrounds in developing rocket engines at SpaceX exposed them to the challenges of existing industrial machines for printing metal components, which they found to be exorbitant, complex, and poorly suited for mass manufacturing.

A New Paradigm in Manufacturing

The objective of Freeform is to design a manufacturing platform that enhances throughput and flexibility while emphasizing active software controls. Palitsch described Freeform’s platform as “AI native,” noting their strategic partnership with Nvidia that provides access to cutting-edge Graphics Processing Units (GPUs).

“I think we’re the only manufacturing company out there that has H200 clusters in a data center on site,” Palitsch remarked. He explained that these clusters enable them to conduct real-time physics-based simulations, which inform various elements of the end-to-end manufacturing workflow.

Data-Driven Manufacturing

The advantage of Freeform’s technology is further enhanced by the data collected from sensors embedded in their manufacturing platform and driven by simulations. This wealth of data allows Freeform to swiftly refine both production quality and quantity.

Cameron Kay, head of talent at Freeform, emphasized the company’s leading position in data acquisition. “We have more meaningful data on the physics of the metal-printing process than any company in the world,” he stated.

Current Developments and Future Plans

Despite not being able to disclose specific clients, Palitsch shared that Freeform is already supplying hundreds of “mission-critical” components to various buyers. As the company’s order backlog expands, Freeform is looking to hire as many as 100 new employees and expand its facilities to better meet demand.

The Growth of Manufacturing-as-a-Service

The concept of Manufacturing-as-a-Service (MaaS) has gained significant traction as venture capitalists increasingly target developments in vehicles, robotics, and energy systems. Comparable companies like Hadrian have recently achieved a $1.6 billion valuation while focusing on automated production for defense applications. Similarly, firms like VulcanForms and Divergent have successfully raised hundreds of millions to advance their own metal-printing services.

Implications for the Future of Manufacturing

As Freeform and others in the MaaS sector continue to grow, the implications for the manufacturing landscape could be profound. The transition toward more automated and AI-driven systems can facilitate faster production times, reduce costs, and improve product quality.

The Role of AI and Real-Time Data

Freeform’s unique approach to integrating AI in manufacturing processes could pioneer new standards. The use of real-time data for decision-making presents an opportunity for continuous improvement—a capability that existing manufacturing processes often lack.

This shift has the potential to democratize manufacturing, allowing more startups and small companies to bring new products to market without the burden of traditional, expensive manufacturing equipment. The flexibility offered by platforms like Freeform can enable a quicker response to market demands and changing consumer needs.

Conclusion

The successful funding round for Freeform is a testament to the growing interest and confidence in innovative startups within the manufacturing sector. The company’s focus on developing an advanced metal 3D printing system aligns well with the ongoing shift toward more efficient, AI-driven manufacturing processes.

As Freeform plans its next steps, including enhancements to its technology and workforce expansion, the future of manufacturing looks promising. By leveraging cutting-edge technology and data-informed decision-making, Freeform is not just aiming to keep pace but to redefine what manufacturing can achieve in the 21st century.

In conclusion, the journey of Freeform reflects a larger narrative in the tech world, where the marriage of software and hardware continues to pave the path for groundbreaking advancements. With robust financial backing and a clear vision, Freeform is poised to become a leader in the fast-evolving landscape of metal 3D printing technology.

Thanks for reading. Please let us know your thoughts and ideas in the comment section down below.

Source link

#Freeform #raises #67M #Series #scale #laser #manufacturing